MMCFs include viscose (also known as rayon), lyocell, and modal. These forest-based fibres are rapidly increasing in popularity; global fibre production increased to a record 113 million tonnes in 2021, and MMCFs were the third most commonly used fibre in 2022[i]. The production volume of these fibres has more than doubled from 3 million tonnes in 1990, to 7.2 million tonnes in 2021 [ii]. These tree-based fibres can be an environmentally friendly alternative to cotton and synthetic materials, but only if they are sourced from responsibly managed forests.

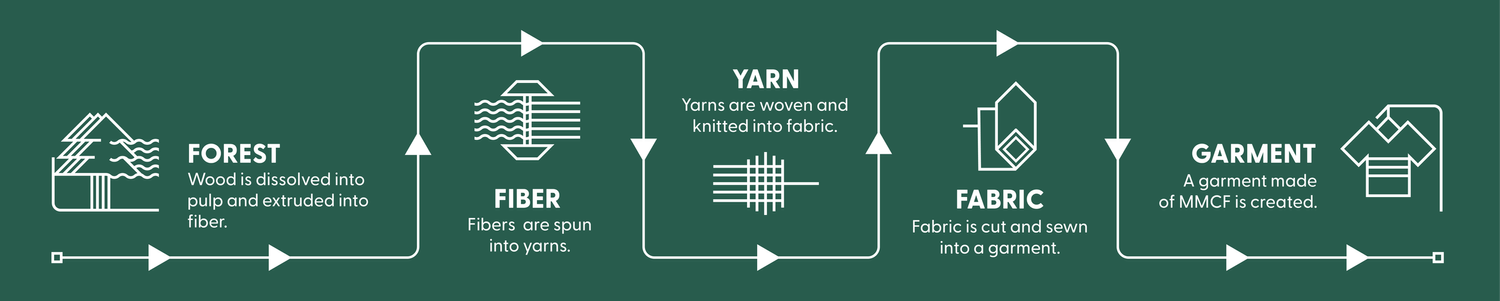

How are MMCFs made?

Despite viscose production dating back to the 19th century, when viscose was used as an affordable substitute for silk, we found that only 12% of people knew that viscose can come from trees in our 2023 consumer survey.

MMCFs are regenerated fibres made from dissolved cellulose, which is found in the walls of plant cells. The plant is chipped into wood pulp, usually the pulp from beech, birch, eucalyptus, fir and poplar trees or bamboo are used. To produce viscose, the pulp is washed, treated, and bleached, then it is treated with carbon disulphide and dissolved in sodium hydroxide to create the solution referred to as ‘viscose’ (hence the name). The solution is forced through a spinneret, a machine that creates filaments, called regenerated cellulose. Then it is spun into yarn, and the fibre is woven or knit into fabric.

As every production process differs, MMCFs can come in various forms, with Lyocell being the most environmentally friendly type. This method uses a non-toxic chemical to dissolve the wood pulp and reuses the chemical component endlessly in a closed loop manufacturing process, making it far more eco-friendly than conventional viscose production.

Are MMCFs sustainable?

Their primary natural resource, trees, and bamboo are what gives MMCFs their reputation for being renewable. This is because plants in themselves are renewable with careful and proper sourcing protocols. MMCFs are considered to be more sustainable than cotton and oil-derived fibres, like polyester and nylon, because the manufacturing process requires less water, less land and also emits less carbon.

Impacts of MMCFs on forests

Whilst this shift away from fossil-fuel derived fibres towards renewable fibres is positive, the MMCF production process could contribute to deforestation if the wood used is not sourced responsibly. It is estimated that 300 million trees are being logged each year to produce MMCFs[iii] and less than 60% of these forest-based fibres are being sourced from certified forests[iv]. Uncertified forests are vulnerable to deforestation and illegal logging, threatening ancient and endangered areas, biodiversity and the communities that rely on forests.

Whilst having a t-shirt made from trees or bamboo may sound eco-friendly, MMCFs cannot be a truly sustainable alternative if they are damaging forests. With uncertified sourcing expected to grow, the fashion industry must take action to clean up their supply chains. A world where forests and sustainable fashion can coexist is possible, but only if MMCFs are sourced from responsibly managed forests.

To add to the above, the fashion industry also needs to improve circularity and start using recycled MMCFs. This would help to reduce the amount of waste going to landfill and alleviate the pressure on forests by reducing the demand for virgin fibre.

What is FSC doing?

Since 2015, we have been working to develop complete FSC-certified textile supply chains to enable retailers to sell clothing and other products with the FSC label, meaning they come from well-managed forests.

FSC-certified forests are managed to strict social, environmental standards to prevent deforestation and forest degradation, protect biodiversity, ensure fair wages and safe working environments, support community rights and protect the rights of Indigenous Peoples.

Fashion Forever Green Pact

We are committed to transforming the fashion industry for a more sustainable future, which is why we launched the Fashion Forever Green Pact. This pact builds on efforts by stakeholders in the sustainability space, such as Canopy’s Canopy Style Initiative. It is a call to immediate action for the fashion industry - brands, retailers, and manufacturers alike - to adopt responsible sourcing to help protect the world’s forests, and the people and wildlife who call them home.

Through a commitment to responsible procurement policies, certified sourcing and FSC labelling, the fashion industry can support the sustainable production of renewable fibres. Joining the pact assures brands are proactive in supporting responsible forestry, manufacturers realise their essential role in maintaining supply chain integrity and consumers are easily able to shop responsibly.

We’re also working to expand our FSC Recycled designation to support the shift towards circular fashion. This label is already applied to paper, packaging, wood, cork, and bamboo products. As technology advances in the recycling of textiles, MMCFs could also be recycled to produce textiles of equal or higher value while at the same time help reduce the pressure on the world’s forests.

References

[i] Textile Exchange (2022). Preferred Fiber & Materials Market Report: https://textileexchange.org/app/uploads/2022/10/Textile-Exchange_PFMR_2022.pdf

[ii] Global Fashion Agenda & The Boston Consulting Group (2019). Pulse of the Fashion Industry: https://web-assets.bcg.com/img-src/Pulse-of-the-Fashion-Industry2019_tcm9-237791.pdf

[iii] Canopy (2023). CanopyStlye Initiative: https://canopyplanet.org/campaigns/canopystyle/

[iv] Textile Exchange (2020). Preferred Fiber & Materials Market Report: https://textileexchange.org/app/uploads/2021/03/Textile-Exchange_Preferred-Fiber-Material-Market-Report_2020.pdf