Last year, JLR (FSC™ N004537) made an industry first commitment to use tyres featuring FSC™-certified natural rubber across its luxury vehicle portfolio. Now, they will be the first in the industry to introduce newly developed tyres containing more than 70% renewable and recycled materials such as silica from rice husks and plant-based resins, at scale.

Tyres with FSC-certified natural rubber were first introduced in 2021 with Pirelli’s breakthrough production of the world’s first Pirelli P ZERO™ tyre using FSC-certified natural rubber. An intense development programme, which started in 2022, showed clear results in terms of reliability and performance, Pirelli (FSC™ N003618) has also translated this success into the realm of motorsport and competitive cycling. By 2026, all natural rubber used in Pirelli’s European factories will be FSC-certified.

In 2024 JLR joined forces with global tyre manufacturer Pirelli, representing a significant step in increasingly sustainable tyre production and adoption, supporting the preservation of forests and promoting sustainable development.

As part of its Reimagine strategy, JLR is fully committed to responsible sourcing, including working to ensure natural rubber used in its tyre production is traceable across every processing stage through to origin.

What’s in a tyre?

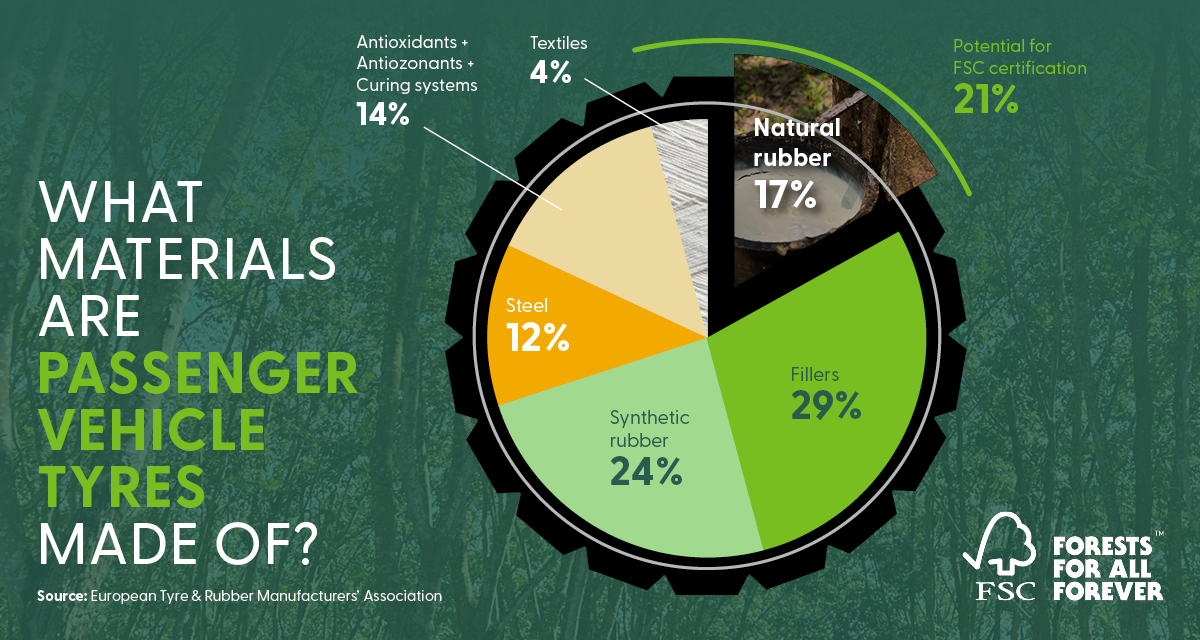

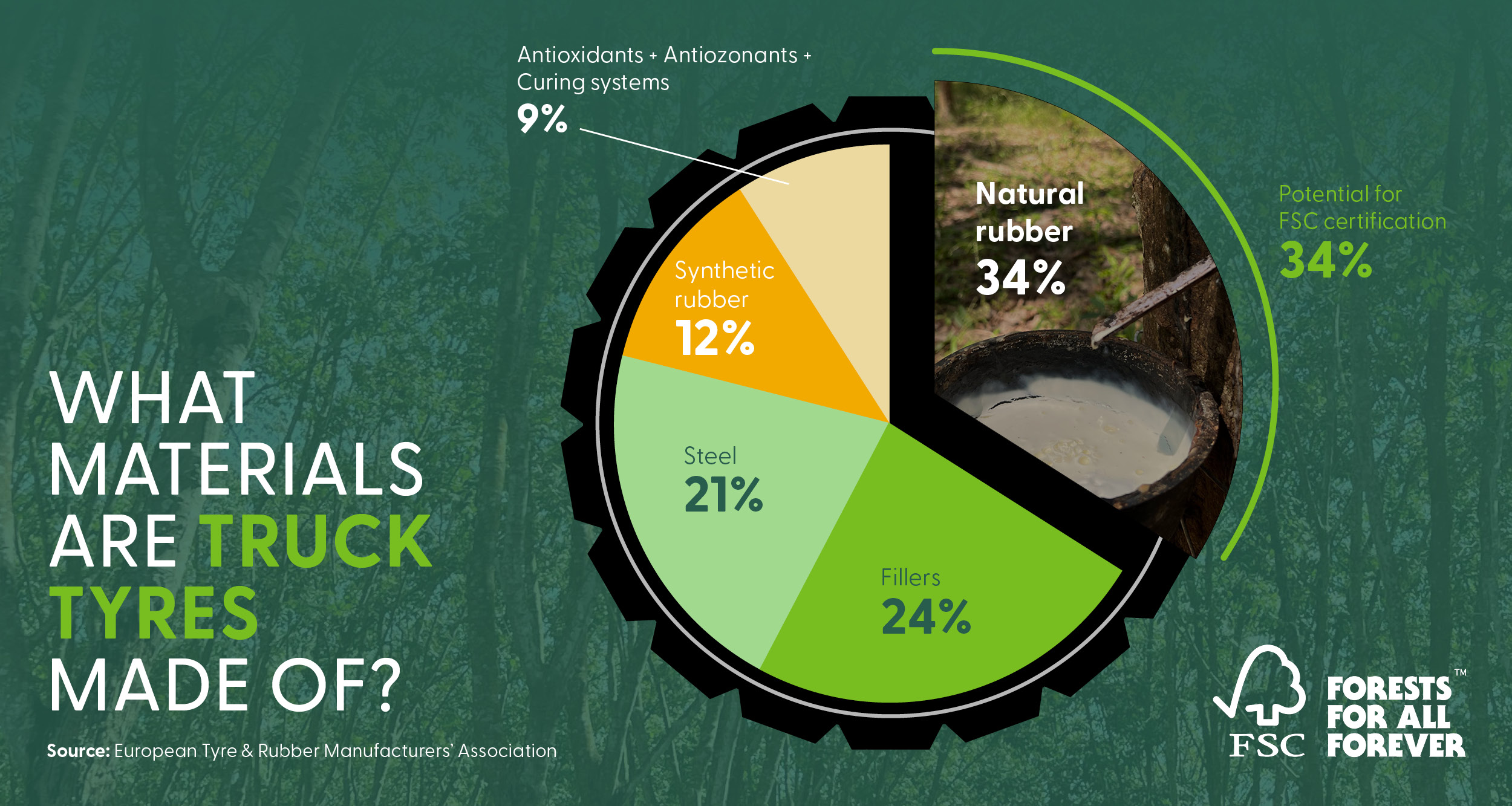

When used in a tyre, natural rubber delivers performance-related benefits and helps boost the product’s tear-and-fatigue crack resistance(1). But it is, of course, only one of several materials conventionally used to manufacture a tyre. Other materials include steel, fillers (such as silica), antioxidants, antiozonants, curing systems (such as zinc oxide), and textiles (such as rayon cord fabric).

- For passenger vehicles and truck tyres, natural rubber comprises between 17 and 34 per cent (2) of the end product.

- Of all the natural rubber produced around the world, a substantial 76 per cent(3) is used by the tyre industry alone.

- Rubber isn’t only featured in its natural form. Synthetic rubber polymers account for 12 to 24 per cent(4) of the tyre composition in passenger vehicles and trucks. For this reason, tyres are FSC-certified as FSC MIX, with the product type ‘natural rubber’

-

Textiles (cord fabrics) account for four per cent of the material used to reinforce tyres in passenger vehicles or trucks. The type of textile can be rayon, polyester, nylon, or aramid. Rayon, like natural rubber, can be FSC-certified (as is the case with JLR’s new tyres). While that’s a seemingly small percentage, combined with natural rubber, the proportion of FSC-certified material could reach from 21 per cent to 34 per cent of every tyre. Our tyre-composition illustrations (see below) highlight the overall potential for everyday transport – from passenger vehicles to light trucks – to contribute to sustainability efforts.

Tyres made with renewable materials

JLR will be the first in the global automotive industry to adopt, at scale, new tyres containing more than 70% renewable and recycled materials such as silica from rice husks, recycled steel, and plant-based resins.

JLR will be the first in the global automotive industry to adopt, at scale, new tyres containing more than 70% renewable and recycled materials such as silica from rice husks, recycled steel, and plant-based resins.

Combining materials with reduced environmental impact without compromise on quality and performance standards for its clients, the new tyres will be available this year as standard on select New Range Rover models where a 22" wheel is specified, ahead of a wider roll-out and aim to expand across its other brands.

Developed with global tyre manufacturer Pirelli specifically for JLR, the new P Zero tyre contains silica, used to enhance wet performance in tyres, sourced from rice husks, a natural by-product of rice milling. Fossil-based polymers and resins, used to help optimise the balance between dry and wet performance, have been replaced with plant-based alternatives such as agricultural by-products or used cooking oils.

The tyres also contain recycled materials, reducing reliance on primary source material to help alleviate resource consumption. Carbon black, a crucial filler in rubber compounds used to improve stability, strength, and durability, is recovered from end-of-life tyres and recycled steel is used to enhance handling and stability.

Bio-based and recycled materials are generally more sustainable to obtain, more energy efficient to process, and easier to manage at end-of-life than virgin and fossil-based materials such as synthetic polymers and silica obtained from conventional materials such as quartz sand, yet perform as well, combining environmental responsibility and high-performance design.

Reuben Chorley, JLR’s Sustainable Industrial Operations Director, said: “This is another example of how JLR is leading on sustainable design innovation in collaboration with its supply chain partners to deliver at scale, while reducing the environmental impact of our products.

“Achieving a more sustainable composition without compromising quality and performance is a challenge because of the complexity of tyre design. But working closely with Pirelli and leveraging both company’s expertise in procurement and engineering, we have been able to deliver this industry first.”

The new P Zero tyre also contains FSC™ (Forest Stewardship Council™) - certified natural rubber and is a result of JLR’s on-going collaboration with Pirelli. In another global first last year, JLR committed to roll-out FSC™-certified natural rubber tyres across its portfolio, to help ensure responsible management of natural rubber in its supply chain. Similarly, all bio and recycled materials used will be third party certified to verify quantity and quality. The two companies have a shared vision to increase the use of recycled and bio-based materials in their products, with an ambition to reach 100% for tyres in the future.

The expanding world of FSC-certified rubber

FSC-certified natural rubber is more visible – and available – than ever before. We’re accelerating the transition to sustainability, but we can’t do it without your support. Keen to help us progress from the racetrack to a global movement? Here’s how you can get involved:

For the rubber industry:

- Brands and Manufacturers: Specify 100% FSC-certified natural rubber in your procurement policies.

- Rubber Smallholder Communities and Collectives (and the Processors and Traders who source from them): Start your certification journey using accessible tools provided by FSC, including group certification, which can certify thousands of rubber farmers.

- To learn more, get in touch with FSC’s rubber expert Sean Nyquist.

For individuals:

References

- U.S. Tire Manufacturers Association [nd] What’s in a tire? USTMA, Washington. https://www.ustires.org/whats-tire-0 (accessed 1 July 2024).

- European Tyre & Rubber Manufacturers’ Association [nd] Natural Rubber. ETRMA, Brussels https://www.etrma.org/key-topics/materials/natural-rubber/ (accessed 1 July 2024).

- European Tyre & Rubber Manufacturers’ Association [nd] Natural Rubber. ETRMA, Brussels https://www.etrma.org/key-topics/materials/natural-rubber/ (accessed 1 July 2024).

- European Tyre & Rubber Manufacturers’ Association [nd] Natural Rubber. ETRMA, Brussels https://www.etrma.org/key-topics/materials/natural-rubber/ (accessed 1 July 2024).