Founded in 2002, Ecodek started life in a small unit based in Chester. Throughout the first few years of business, it was a matter of trial and error, as wood polymer composite decking was pretty much unheard of within the UK. Whilst completing research and development, Ecodek took the initiative to import and resell an American product, as the American wood polymer composite market had been thriving for at least fifteen years. Due to the popularity of the product, in 2004, Ecodek were able to double in size, acquiring in addition the unit next door to allow for increased production capacity and a bigger team to start to produce Ecodek decking boards in house.

Some of their customers began to request certification, so Ecodek were motivated to become FSC-certified to meet this demand. The polymer is used in a range of their products and is recycled, so it made sense to ensure the wood that is also used in their products was recycled or sustainably sourced too. Ecodek products are carefully designed and crafted to give the customer the benefits of real wood without the hassle. Ecodek Wood Polymer Composite boards are solid, more impact and moisture resistant than hollow decking and easy to install.

Ecodek have seen successes in sustainability due to most construction projects now pushing for sustainability and responsible sourcing. This helped them secure business opportunities they would have lost if they were not certified.

FSC certification fits very well with Ecodek’s business. Recycled materials are used as much as possible. All scrap from production is recycled and reused, so it makes perfect sense to ensure Ecodek’s wood is sourced to similar standards.

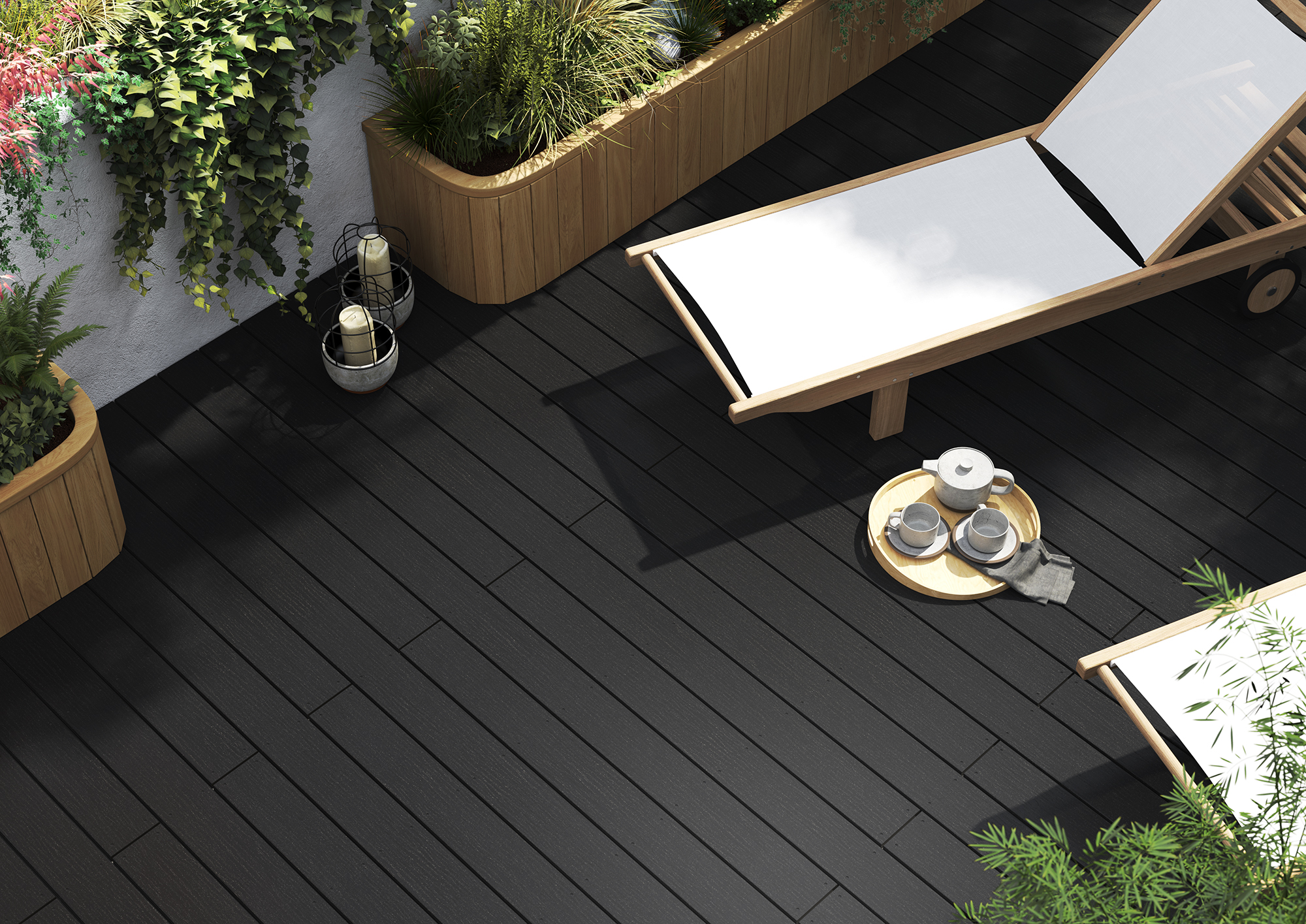

Ecodek produce and sell a variety of decking products & other timber substituted products, those ranges called Signature AT, Signature HD, Heritage, and Stadia.

A relatively simple FSC auditing system was introduced at the start, which was used whenever they produced products to FSC requirements. There have been some subtle changes over the years, which Ecodek have adapted. The business has passed every audit so far. Some audits have carried a minor non-conformity, which was rectified swiftly following guidance from Ecodek’s auditor.

Ensuring all paperwork is correct from start to finish can be challenging when meeting FSC requirements. This involves suppliers quoting correct order numbers, product references & weights on all communication, and details such as chain of custody details back to the forest. Once the material arrives at Ecodek, they then need to control the wood through the system and record the correct information. There’s lots of room for errors to be made, so attention to detail and a meticulous eye is essential to the job.

Even though Ecodek runs a fairly straight forward system, it took quite a bit of time and effort to setup. It’s important that all stakeholders are aware of their responsibilities. Ecodek works with a third party advisor, who has been with them since the start of its implementation. For companies who are looking to be FSC-certified Ecodek advise to do the same, as the advisor has ensured they stay on top of things, and had helped to prepare them really well for audits.